Partial Discharge Tester

Portable and On-line Partial Discharge Monitoring System

is an electrical discharge that occurs across a portion of the insulation between two conducting electrodes, without completely bridging the gap. Partial discharge’s are caused when there is a discontinuity in the insulation system and as a general ‘rule-of-thumb’ Partial discharge will occur in systems operating at voltages of 3000V and above, although it should be noted that partial discharge can occur at lower voltages than this.

Partial discharges can occur in voids in solid insulation (paper, polymer etc), along the interfaces of multi-layer solid insulation systems, in gas bubbles in liquid insulation or around an electrode in a gas (corona discharge).

Partial Discharge activity can initiate under normal working conditions in high voltage equipment where the insulation condition has deteriorated with age, has been aged prematurely by thermal or electrical over-stressing or due to improper installation.

Partial discharge can also propagate and develop into electrical trees and interfacial tracking until the insulation is so weakened that it fails completely with breakdown to earth or between the phases of a 3-phase system. Depending on the discontinuity in the insulation system and where it is positioned, a failure can take anything from a few hours up to several years to track through to produce a complete earth or phase-phase fault.

It is known that whilst some discharges can be extremely dangerous to the health of the insulation system (e.g. discharges within polymeric cables and cable accessories) whilst other types of discharge can be relatively benign (e.g. such as corona into air from sharp, exposed points on HV overhead networks or on the outside surfaces of outdoor cable sealing ends). The key to on-line, diagnostic Partial Discharge testing is to be able to differentiate between the dangerous and the benign. This becomes more difficult as the voltage of the system increases.

Failure of High Voltage insulation is the No.1 cause of HV system failures with statistics indicating that electrical insulation deterioration causes up to 90% of electrical failures of certain high voltage equipment.

On-line Partial Discharge testing of MV and HV plant gives an advance warning of pending insulation failure, thereby allowing the plant owner to take remedial maintenance action during planned outages. In general, the earlier the advance warning can be made, the cheaper the maintenance or intervention costs will be.

Unlike off-line testing, on-line Partial Discharge testing and monitoring gives an accurate picture of the HV plant’s health and performance under normal service conditions including the effect of load, temperature and humidity.

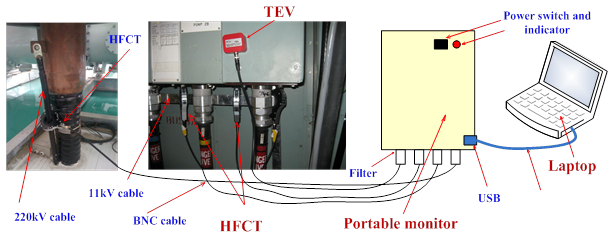

Based on over 10 years’ research, with the support of numerous UK and Chinese utilities, the portable Cable PD monitoring systems was developed and has the following features:

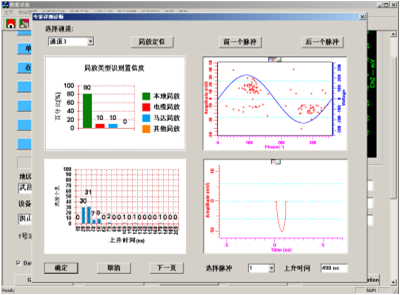

- Bespoke software package – allowing data acquisition, signal denoising and classification, PD defect site diagnosis and localisation to be carried out in an autonomous manner.

- User-friendly graphical-user-interface (GUI) — allowing interrogation of results to be carried out by human experts conveniently;

- A hardware/software filter system – that will complement the software to deal with the strong noise that may be present in power generating stations;

- A database management system – allowing cable asset information to be effectively managed and PD testing results trend-analysed.

- • The solution can be implemented as a portable PD testing equipment as well as an on-line continuous monitoring system.

HV Plant Asset and Risk Management

Partial Discharge testing is particularly important where the MV/HV plant has a high ‘criticality’ to the operation of a client’s network. This may be due to its age, historical failures or the consequences of its failure (position in the network).

Qualification of Partial Discharge ‘criticality’ within the plant owner’s HV network can be achieved quickly and easily using on-line, screening and diagnostic PD test technology to provide an ‘early warning system’ for these incipient insulation faults.

PD Monitoring and Trend Analysis

On-line Partial Discharge testing allows for analysis trends in PD activity to be observed over time. This may reveal correlation with environmental (temperature, humidity etc) or service conditions (changes in load etc). As PD activity is often present well in advance of insulation failure it is possible by observing its development that strategic decisions can be made about refurbishing and renewal programmes.

Benefits of On-Line Partial Discharge Field Measurements

- It is truly a predictive test, indicating insulation degradation in advance of the failure.

- It is a nonintrusive test, requiring no interruption of service and is performed under

normal operating voltage, load and environmental conditions. - It is a nondestructive test; it does not test to failure or adversely affect the

equipment under test in any way. - It does not use any overvoltage, thereby not exposing the tested equipment to higher voltage stresses than those encountered under normal operating conditions.

- Trending can be accomplished by storing baseline measurement results to allow comparison with future tests.

- In many instances the site of the partial discharge occurrence can be located within

the cable/plant under test, so the localised problem can be repaired. - The cost to perform a PD

survey is relatively inexpensive compared with off-line testing, allowing annual surveys to be performed economically at most facilities.

Examples of HV & MV Plant That Can Be Tested

- Cables and Cable Accessories (terminations and joints)

- Switchgear (AIS, SIS and GIS)

- Instrument transformers (voltage and current)

- Power transformers and bushings

- Motors and generators

- Surge arrestors

- Capacitors

For further information on cost of the Partial Discharge Monitoring System and advice on partial discharge testing please get in touch.

Comments or questions are welcome.